Tianjin Jinhe Bimetal Wire Co Ltd

Payment Terms: TT or LC

Ref Price : US $0.10-$10.00

Quality Product

Quality Product

Credit Purchasing

Credit Purchasing

Credit Rating

Credit Rating

Timely Delivery

Timely Delivery

Credit Services

Credit Services

Overview

Quick Details:

1 Place of Origin: Tianjin, China 2 Alloy Or Not:Is Alloy

3 Al (Min):<0.10 4 Ultimate Strength (≥ MPa):25 Mpa

5 Elongation (≥ %):18% 6 Conductivity:yes

7 Model Number:ER1100 8 Application:bicycles, aluminium scoter

9 Wire Gauge:1.20MM 10 Product name:Aluminum Alloy 1100 Wire

11 Color:steel 12 Material:aluminum alloy

13 Key words:mig aluminum welding wire 14 Certificate:CCS CE

15 Grade:1100 16 Type:MIG

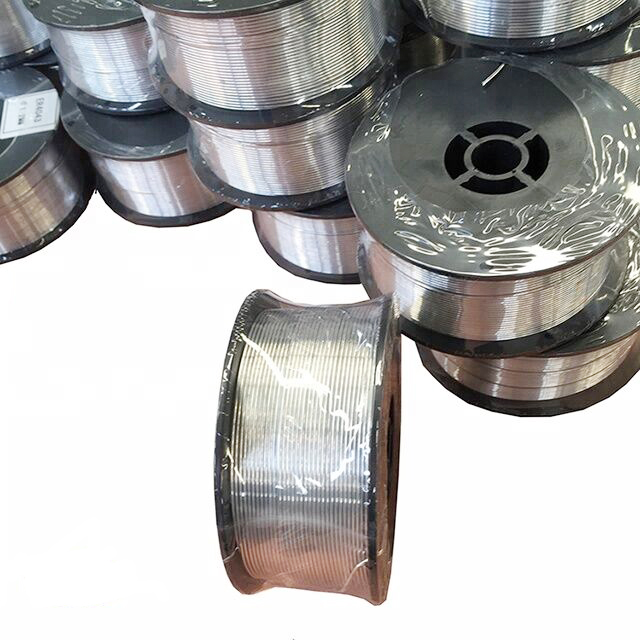

PACKING:Packaging Details

Specification:MIG-wires 0.8mm,0.9mm,1.0mm,1.2mm,1.6mm2.0mm,2.4mm

MIG Packing:0.5kg, 1kg,2kg, 6kg, 7kg/plastic spool

Port:Tianjin, China

Lead Time:20days

ER1100 MIG ALUMINIUM WELDING WIRE FOR PACKING IN SPOOL1.20MM in 6-7KG/SPOOL

Aluminum welding wire is specialized in production pure aluminum welding rod, aluminum magnesium welding rod, aluminum silicon welding rod, low silicon welding rod, high silicon welding rod.The aluminum welding wires are widely used in bicycles, aluminium scoter, engine carriage, pressure vessel, armary processing, ship-building, space shuttle etc.

|

AWS A 5-10 Data |

ER1060 |

ER1100 |

ER2319 |

ER4043 |

ER4047 |

ER5356 |

ER5183 |

ER5556 |

|

|

Typical composition in% |

Si |

<0.25 |

Si+Fe<0.95 |

<0.20 |

4.50-5.50 |

11.00-13.00 |

<0.25 |

<0.40 |

<0.25 |

|

Fe |

<0.35 |

<0.30 |

<0.80 |

<0.60 |

<0.40 |

<0.40 |

<0.40 |

||

|

Cu |

<0.05 |

0.05-0.20 |

5.80-6.80 |

<0.30 |

<0.30 |

<0.10 |

<0.10 |

<0.10 |

|

|

Mn |

<0.03 |

<0.05 |

0.20-0.40 |

<0.05 |

<0.15 |

0.05-0.20 |

0.50-1.00 |

0.60-1.00 |

|

|

Mg |

<0.03 |

- |

<0.02 |

<0.05 |

<0.10 |

4.50-5.50 |

4.30-5.20 |

4.70-5.50 |

|

|

Cr |

- |

- |

0.05-0.20 |

0.05-0.25 |

0.05-0.20 |

||||

|

Zn |

<0.05 |

<0.10 |

<0.10 |

<0.10 |

<0.20 |

<0.10 |

<0.25 |

<0.20 |

|

|

Be |

- |

<0.0008 |

<0.0003 |

<0.0003 |

<0.0003 |

<0.0003 |

<0.0003 |

<0.0003 |

|

|

Ti |

<0.03 |

- |

0.10-0.20 |

<0.20 |

<0.15 |

0.06-0.20 |

<0.15 |

0.05-0.20 |

|

|

Physical properties(Approx. Values) |

0.2% yield strength Rp0.2 Mpa |

20 |

25 |

180 |

40 |

60 |

110 |

125 |

125 |

|

Tensile strength Rm Mpa |

65 |

80 |

240 |

120 |

130 |

240 |

275 |

275 |

|

|

Elongation A5(L0=5d0) % |

18 |

25 |

Ca.3 |

8 |

5 |

17 |

17 |

17 |

|

|

Test temperature ℃ |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

|

AWS A5.10 |

Joint Strength |

Parent metal |

Characteristics |

|

Standard |

(Mpa) |

||

|

ER1070 |

Above 55 |

Pure aluminum series105010701080 |

Good anti-corrosive and plasticity |

|

ER1100 |

80-110 |

Pure aluminum series1100 |

Good anti-corrosive and plasticity |

|

ER1200 |

80-110 |

Pure aluminum series1200 |

Good anti-corrosive and plasticity |

|

ER2319 |

400-450 |

Pure aluminum series2219 |

High intensity after heat treatment |

|

ER4043 |

170-250 |

Al-Mg-Si casting aluminum |

The anti-thermal crack performance of the welded joint is good, but the plasticity, toughness are low, becomes grey black after anodic process |

|

ER4047 |

170-250 |

Casting Al. ,Al-Cu casting ,Ag-Mg-Si casting |

The anti-thermal crack performance of the welded joint is good, but the plasticity, toughness are low, becomes grey black after anodic process |

|

ER4145 |

200-300 |

Al-Cucasting20142017 |

The anti-thermal crack performance of the welded joint is good, but the plasticity, toughness are low, becomes grey black after anodic process |

|

ER5554 |

180-240 |

low Mg content5052,5454casting |

Use chemical equipment with a temperature above 65 |

|

ER5654 |

210-270 |

medium Mg content5154casting |

medium intensity,good anti-corrosive |

|

ER5356 |

270-310 |

Al-Mg casting, Al-Mg-Si casting, Al-Zn-Mg casting |

Typical welding wire used most widely, good mechanics performance and anti-corrosiveness |

|

ER5556 |

280-320 |

Al-Zn-Mg casting, Al-Mg casting |

The connector intensity is high, and the moulding performance and tenacity is inferior to 5183 |

|

ER5183 |

280-310 |

Al-Mgcasting5083 |

Typical welding wire used most widely, good mechanical performance and anti-corrosiveness |

Specifications: MIG-wires, 0.8mm,0.9mm,1.0mm,1.2mm,1.6mm2.0mm,2.4mm

TIG-rods, 1.6mm,2.0mm,2.4mm,3.2mm,4.0mm,5.0mm, 6.0mm

MIG Packing:0.5kg, 1kg,2kg, 6kg, 7kg/plastic spool

TIG Packing: 5kg, 10kg per paper box or plastic box, Length 1.000mm

aluminum welding wire professional manufactory

high toughness

good forge ability

well anti-corrosiveness

good choice for color-match

Notice of usage and storage

1 You can do welding directly in effect without any processing before welding after opening the box of products,The products will be in effect more than two years on condition they are of good packing in seal.

2 The products should be put to the place where is of aeration and dryness and away from the medium of acidalkalioil and so on.

3 The products should be avoided of crack and damp during delivery so as to avoid destroying the welding spools and impacting the quality of welding wires.

4 We suggest you to put some dust-proof on the surface of wires after the packages are moved from the products.

5 We suggest you to do some processing to the surface of the wires before welding when you use the wires out of storage life.

6 The arc welding may hurt your eyes during welding. please protect yourself.

Contact Information:

Email:

Jhbm@sino-sources.com

The electric aluminum rod produced by Tianjin Jinhe Double Metal Wire Co., Ltd. is mainly used for the production of enamelled aluminum wire and copper clad aluminum wire. It is the first enterprise in China to produce aluminum rods for enameled aluminum wire and copper clad aluminum wire. . Through hundreds of experiments and technological innovations over the past five years, the company has explored a set of aluminum rod production processes suitable for enameled aluminum wire and copper clad aluminum wire products and accumulated a large number of production practice experience. The product quality is stable and reliable. The lacquered aluminum wire and copper clad aluminum wire manufacturers praise. The company has established long-term friendly cooperative relations with Tongling Jingxun, Galanz Electric, Weiqi Electric, Wuxi Meida, Datongfa, Zhangjiagang Shengtian and other large enterprises that produce enameled wire and copper-clad aluminum.

While occupying the domestic market, our company has been involved in overseas markets since 2006. After nearly two years of development and development, our products have been exported to more than ten countries and regions such as North America, Europe, Africa, West Asia, Southeast Asia, Japan and Korea. The annual export volume is 30,000 tons, and it has established good cooperative relations with GE, HDM, Germany SIEMENS, Korea HIHO, SAMJIN and other companies. The export product implementation standards refer to ASTM B233 and EN AW 1350/1370.

"Jinhe" brand electrician aluminum rod has been widely used in domestic electromagnetic wire, enamelled aluminum wire, copper clad aluminum wire, wire and cable, metallurgy, electrical refrigeration and food industries such as GB/T3954-2001. The company currently has a total of 6 aluminum rod production lines, annual consumption of 210,000 tons of aluminum ingots, annual output of aluminum rods of 200,000 tons, is the country's largest electrical aluminum rod processing base. The company's quality assurance system is sound, has passed ISO9001: 2000 quality management system certification, products have passed SGS testing, in line with EU RoHS directives, our company has advanced production equipment, reasonable technology, leading technology, stable and reliable product quality, praised by customers for many years. . Our company has always been based on product quality and the basis of development; to meet customer needs for business purposes; to pursue the maximization of customer benefits as the primary goal, and strive to create "Jinhe" brand.