Cangzhou Qianjinyawa Machinery Manufacturing Co., Ltd.

Payment Terms: TT or LC

Ref Price : US $8,000-12,000 / Set

Supply Capability : 30 Set/Sets per Month Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine

Loading Port : TianJin

Inquire Now Quality Product

Quality Product

Credit Purchasing

Credit Purchasing

Credit Rating

Credit Rating

Timely Delivery

Timely Delivery

Credit Services

Credit Services

Quick Details

Type:

Steel Frame & Purlin Machine

Condition:

New

Work Pressure:

Normal Pressures

Production Capacity:

30-40M/MIN

Place of Origin:

Hebei, China (Mainland)

Brand Name:

QIANJIN

Model Number:

C75

Voltage:

380V/50HZ 3Phase(as Customer's Request)

Power(W):

5.5kw

Dimension(L*W*H):

4500*900*1100mm

Weight:

3 Tons

Certification:

CE/ISO9001

Warranty:

18 Months

After-sales Service Provided:

Engineers available to service machinery overseas

Control system:

Delta

Decoiler:

1.5t Manual Decoiler

Product name:

Stud Track Roll Forming Machine

Usage:

Steel Structure

Cutting blade material:

Cr12 Mov

Roller Material:

Cr12

Color:

Grey

Shaft material:

High Grade No.45 Steel

Transmission:

Gear

Driving:

Electrical motor

Packaging & Delivery

Packaging Details

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine :

Main body is packed by plastic film and fixed well by wire rope in container, rollers are painted by rust oil. Spare parts are packed by carton box

Delivery Time

45 days after receive advance payment

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine

Product Description

The finished product of roll forming machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

|

No. |

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine |

|

|

1 |

Suitable material |

PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

|

2 |

Thickness of coil sheet |

0.2-0.6mm |

|

3 |

Usage |

Light steel keel |

|

4 |

Effective width |

75mm |

|

5 |

Material of main frame |

600H steel |

|

6 |

Diameter of Soild shaft |

70mm, high grade 45# steel |

|

7 |

Roller |

High grade 45# steel, quenched and tempered treatment, hard chrome plated 0.05-0.07mm |

|

8 |

Thickness of middle plate |

16mm, 45# steel plate |

|

9 |

Forming station |

14rows |

|

10 |

Drive type |

By chain(1.0 inch), link bearing model 6210 |

|

11 |

Power of main motor |

5.5 kw, Lichao, Shanghai, with reducer |

|

12 |

Sidewall connection bar |

25mm, zinc plated |

|

13 |

Forming speed |

About 12-18m/min |

|

14 |

Hydraulic pump station |

4.0 kw, 40# hydraulic oil |

|

15 |

PLC |

DELTA(TAIWAN)/Mitsubishi |

|

16 |

Material of razor blades |

Cr 12, quenching 58-62℃ |

|

17 |

Frequency converter |

It has the advantage of slowing down before cutting, to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

|

18 |

Switch |

CHNT |

|

19 |

Frequency changer |

SAJ |

Our Services

| Item | Name | Qty |

| 1 | Manual Decoiler | 1 |

| 2 | Feeding platform with hand cutting system | 1 |

| 3 | Main forming system | 1 |

| 4 | Hydraulic cutting system | 1 |

| 5 | Hydraulic pump station | 1 |

| 6 | Electrical motor | 1 |

| 7 | PLC control system | 1 |

| 8 | Touch screen operation | 1 |

| 9 | Finished products receive table | 1 |

| 10 | Safety shield(optional) | 1 |

Product Overviews

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine(Feeding platform)

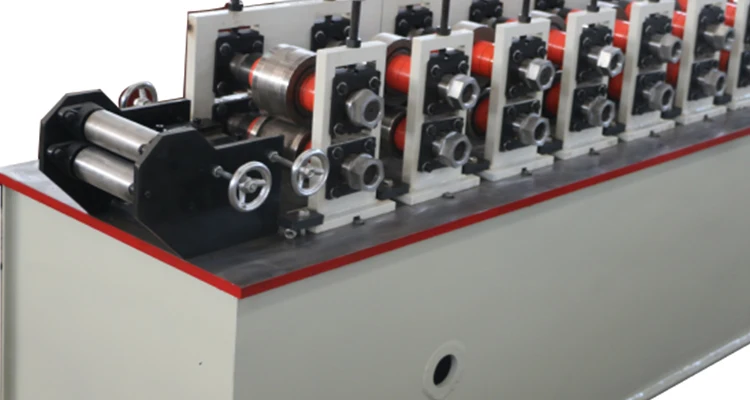

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine(roll forming system)

|

Roller station |

12 Steps+3Straighting rollers |

|

|

Shaft Diameter |

50mm-0.01mm with Key-way |

|

|

Roller Material |

Cr12 with key-way |

|

|

Heat Treatment |

Vacuum quenching upto hardness 58℃ |

|

|

Fine Machining |

CNC Lathe after vacuum quenching |

|

|

Machine Structure |

5mm under-frame and 20mm worktable |

|

|

Motor Power |

5.5KW with PM250(or K-type )Reducer |

|

|

Transmission Method |

All gear with high frequency quenching |

|

|

Memorial Gateway |

25mm thickness A3 Plate |

|

|

Gateway Process |

Square side with fly edge machine |

|

|

Production Speed |

30-40m/min |

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine(hydraulic cutting system)

|

Cutting Method |

Full-auto hydraulic servo-tracking cutting |

|

|

Hydraulic System |

5.5KW(if hot-weather with water-cooling) |

|

|

Speed Adjustment |

Frequency Changer Control |

|

|

Cutter Material |

Cr12Mov |

|

|

Cutter Processing |

electric spark,polishing machine and wire-electrode cuttingafter heat-treatment |

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine(hidden driving motor)

Gypsum Drywall Profile Metal Stud And Track Roll Forming Machine(embossing and stamping)

Manual Decoiler(1.5T)

|

|

Un-coiler Type |

Manual Operation |

|

Loading Capacity |

Max 1500KG |

|

|

Inner Coil Diameter |

460-510mm |

Receiving Table(3M)

|

|

Total Length |

3000mm |

|

Frame Structure |

Angle Steel with Metal Plate |

|

|

Function |

Let the finished production freely |

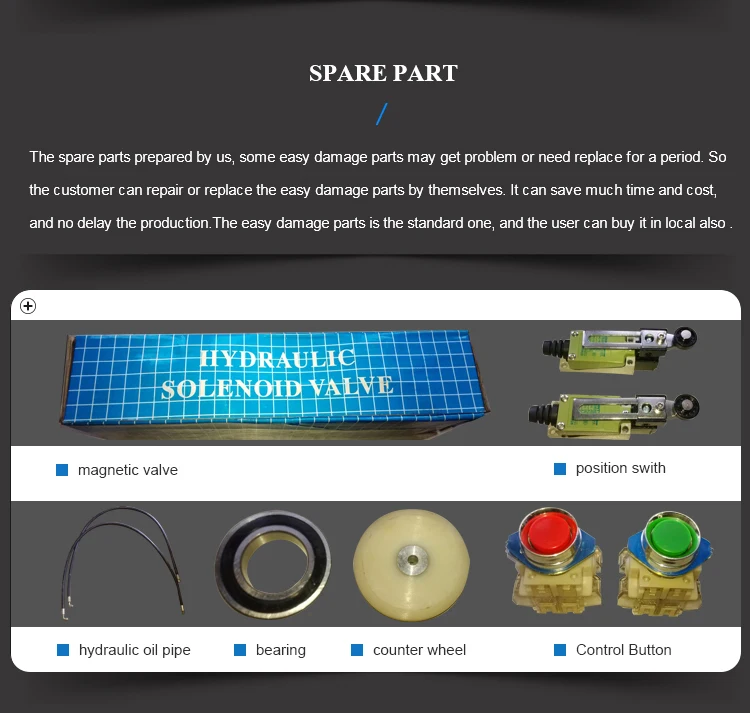

Spare Part

PARAMETER & SPECIFIC

Certifications

International Certification: CE, ISO 9001, BV. Please kindly check our business license for your confirmation.

About Us

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd.

We have been devoted to designing, developing and manufacturing pressure equipment for 10 years. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

Our main products are all construction equipment ,such as color steel roofing sheet roll forming machines, C&Z purline machine, steel roof tile roll forming machines, floor deck forming machines, EPS sandwich panel roll forming machine, highway guardrail forming machine, shearing machine, bending machine, slitting machine.