Aluminum silicate fiber cotton board supplier

Payment Terms: TT or LC

Ref Price : 3-10 USD/SQUARE METERS

Global Trade Service Pledge

-

Quality Product

Quality Product

-

Credit Purchasing

Credit Purchasing

-

Credit Rating

Credit Rating

-

Timely Delivery

Timely Delivery

-

Order On-line Tracking

Order On-line Tracking

-

Credit Services

Credit Services

Quick Details

-

Place of Origin:Tianjin China (Mainland)

-

Brand Name:wmdtrade

-

Model Number:Aluminum silicate

-

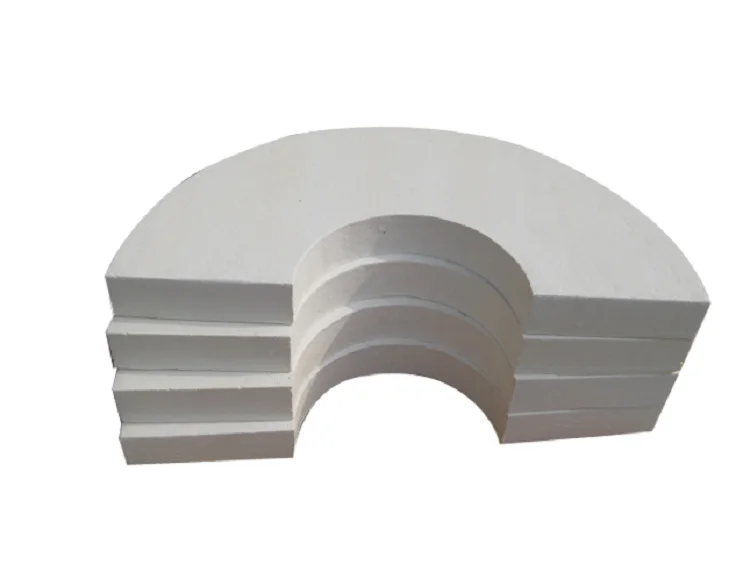

Name:Aluminum silicate fiber board

-

Grade:Class A

-

Length:600mm

-

Width :400mm

-

Thickness:20-100(mm)

-

Working temperature:1000-1350℃

-

Mild tension:Strong

-

Color:White

-

Port:Tianjin xingang

white oven heat insulation aluminum silicate fiber board

Product Description

The aluminum silicate board is rigid product made of different ceramic fiber bulks with excellent chemical stability, organic and inorganic bond by wet method and vacuum forming processing which is applied to many kinds of industries.

They are manufactured over a wide range of grades densities and hardness.

aluminum silicate board Product Characteristic:

1,Excellent pressure resistance & long service life

2,Low thermal storage & low thermal conductivity

3,Non-crisp material ,excellent tenacity

4,Accurate Dimension & excellent flatness

5,easy for cutting & convenience construction

6,Excellent wind corrosion resistance

7,Continuous production, well—distributed fibers & excellent stability

aluminum silicate board Application Range:

Insulating material of back lining for furnaces in the fields of cement and other building materials, petrochemical, metallurgy, ceramics and glass, heat treatment, non-ferrous metals, high temperature reaction and heating equipment.

aluminum silicate board Technical Index:

|

product code |

MYTX-PT-04 |

MYTX-BZ-04 |

MYTX-GC-04 |

MYTX-GL-04 |

MYTX-DG-04 |

MYTX-HG-04 |

|

heating permanent linear change(%) |

950℃×24h≤-4 |

1000℃×24h≤-4 |

1100℃×24h≤-4 |

1200℃×24h≤-4 |

1250℃×24h≤-4 |

1350℃×24h≤-4 |

|

heat conductivity(An average of 500℃)W/(m.k) |

≤0.165 |

|||||

|

water conten rate (%) |

≤-1.5 |

|||||

|

Organic material content (%) |

≤-6 |

|||||

|

Theoretical volume density ( kg/m3) kg/m3 |

250-280 |

280-320 |

320 |

320 |

320 |

320 |

|

Al2O3 |

≥40 |

≥43 |

44-47 |

51-53 |

43-45 |

|

|

Al2O3+SiO2 |

≥95 |

≥96 |

≥98 |

≥99 |

≥90 |

|

|

Al2O3+SiO2+ZrO2 |

99 |

|||||

|

ZrO2 |

5--7 |

≥15 |

||||

|

Fe2O3 |

<0.5 |

<0.5 |

≤0.3 |

≤0.3 |

≤0.3 |

|

|

Na2O+K2O+Fe2O3 |

<0.9 |

|||||

|

Product specification (mm)(customized according to customer demand) |

Normal length and width, thickness 3mm-100mm |

|||||

|

Packing form |

paper box |

|||||

|

Quality and environment system certification |

ISO9001-2008, ISO14001-2004 |

|||||

Characteristics

-

Strong pressive strength

-

Good erosion resistance

-

Shorter heat up and cool down time

-

non-brittle material, good elasticity

-

heat capacity and low thermal conductivity

-

excellent chemical stability and thermal stablity

-

good thermal shock resistance

-

high compressive strength

-

heat resistance for fireplace

Application

-

Heat insulation for back lining of high temperature industrial furnace

-

Hot surface of industrial furnace ,electric furnace ,porcelain furnace, heat treatment furnace, mechanical and metallurgical furnace

-

Combustion chamber construction

-

Ceramic industry (kiln lining, kiln car insulation )

-

Glass industry(glass tank wall, side, end wall and port neck insulation)

-

heat resistance for fireplace

-

heat insulation of high temperature and high heat equipment

![]()

FAQ

1.Are you a trader or manufacturer?

A: We are manufacturer, we have own factory.

2.What is the delivery time?

A: About 10-20 days after the contract signing.

3.Can you provide sample?

A: Yes, we can offer sample , and some samples are free.

4. Can you delivery by express?

A: Yes, we can delivery by any express

5.What is your payment methods?

A: Payment terms :T/T 30%-50% deposit after order confirm ,the balance after goods ready before shipping or L/C.

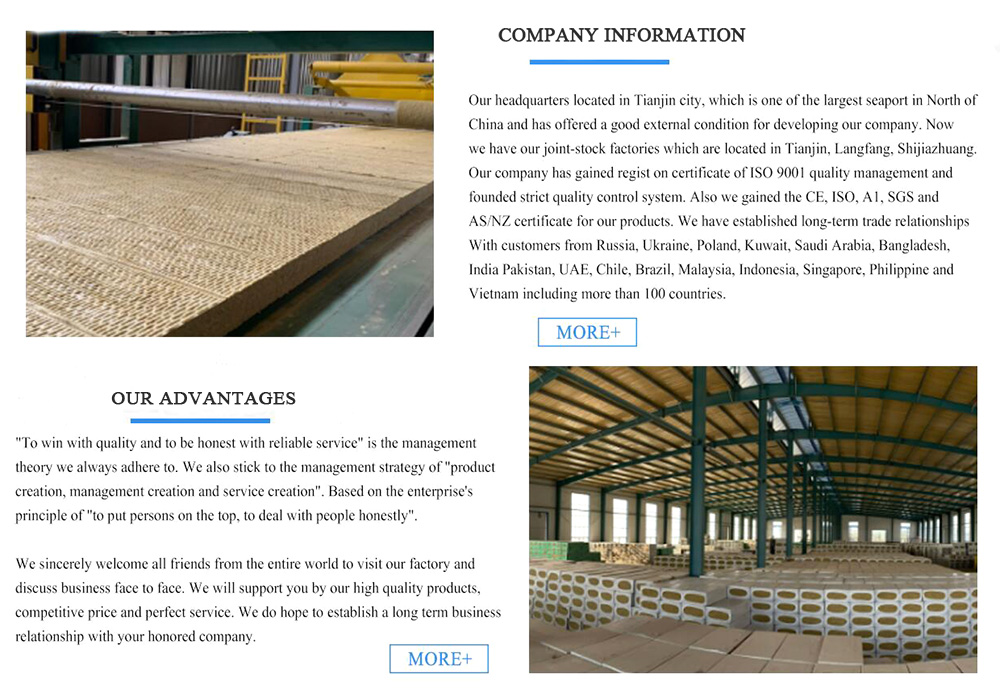

WanMaiDe estabished in 2001, a leading manufacturer and exporter of Glass Wool, Rock Wool, Rubber Foam, Foam Glass,Extrude Polystyrene/XPS, Phenolic foam board insulation in China. After more than 20 years' development, we totally have 10 producing lines for glass wool insulation,5 producing lines for rock wool insulation and more than 30 producing lines for rubber foam insulation.

We had mad OEM production for WANMAIDE which are popular due to the high quality and competitive price all over the world.

Collection

Collection