Custom valve insulation jackets supplied by factory directly

Payment Terms: TT or LC

Ref Price : 10-350 USD/PIECE

Global Trade Service Pledge

-

Quality Product

Quality Product

-

Credit Purchasing

Credit Purchasing

-

Credit Rating

Credit Rating

-

Timely Delivery

Timely Delivery

-

Order On-line Tracking

Order On-line Tracking

-

Credit Services

Credit Services

Quick Details

-

Place of Origin:Tianjin China (Mainland)

-

Brand Name:wmdtrade

-

Model Number:Removable insulation jacket

-

Type:Heat Insulation Materials

-

Product Name:Removable insualtion jacket

-

Material:Fiberglass/ceramic

-

Temperture:1000℃

-

Advantage:Removable,reusable,flexible

-

Thermal conductivity:0.033-0,044

-

Name:Waterproof Thermal Insulation

-

Port:Tianjin xingang

Product Description

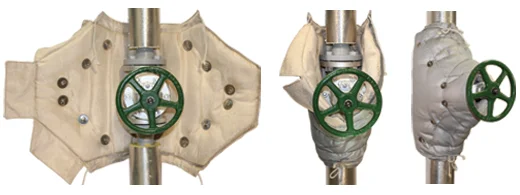

Take advantage of up to 40% Energy Savings--- Thermal insulation jacket for valve

DRAGONPOWER valve insulation jacket are the leading brand of purpose designed reusable covers offering excellent insulation benefits for a wide variety of equipment including valves, flanges, calorifiers, strainers, separators, actuators, heat exchangers, elbow bends, etc.

The removable valve insulation jacket can be fabricated in many different ways depending on the materials used, the application and the customer requirements. Usually, the valve insulation jacket consists of surface layer, insulation layer, and liner and/or anti-abrasion layer inside. Seams are sewn with high temperature threads, usually with Kevlar TM, PTFE coated glass fiber or stainless steel thread to suit application.

This specialist insulation product can offer superb savings of up to 40% on barrel heating and is manufactured with the support of over 40 years of experience, so quality is guaranteed.

-

Savings of between 25-40% on energy bills

-

Personnel protection from heat fatigue and possible skin burns

-

Easy fitting and removal for maintenance

-

Quicker start-up time

-

Extended heater band life

-

Rapid pay-back/savings time

-

Safe to touch

-

Jackets reduce Peaks and total metered heat energy load

-

Made from heat-resistant materials

-

Jackets resist steady temperatures of around 350ºC/662ºF with temporary peaks of approximately 450ºC/842ºF (higher resistant jackets available upon request)

-

Cut-outs for junction boxes and thermocouples

Removable cover

Type 1: HLBIII ≤160℃

Inner layer: two side-coated silica gel cloth

Insulation layer: fiberglass needle felt (thickness 15mm/30mm)

Outer layer: two side-coated silica gel cloth

Type 2: HLB IV≤650℃

Inner layer: aluminum silicate fiber cloth

Insulation layer: aluminum silicate fiber blanker (thickness 40-100mm)

Outer layer: two side-coated silica gel cloth

Type 3: HLB V≤1000℃

Inner layer: high SiO2 fiber cloth

Insulation layer: aluminum silicate fiber blanket (thickness 40-100mm)

Outer layer: teo side-coated silica gel cloth

Traditional Insulation system Removable insulation system

Structure: Rockwool+Metal cladding Structure: one-piece component

1. Hard to remove, lower work efficience 1. Easy to remove, increase work efficience

2. Cannot secondary usage once removed 2. Repeatedly used if removed

3. Easy to lost heat efficience 3. Prevent heat loss

4. Lower production cost but waste manpower cost 4. Higher production cost but save manpower cost

Step 1: place the cove to right position Step 2: wrap the cover to pipe fitting Step3: fix the cover

»» Valves »» Flanges »» Fittings »» Strainers

»» Pipes »» Filters & regulators »» Pumps »»Manifolds

»» Sight glasses »» DeSuper heaters »» Heaters »» Steam Traps

WanMaiDe estabished in 2001, a leading manufacturer and exporter of Glass Wool, Rock Wool, Rubber Foam, Foam Glass,Extrude Polystyrene/XPS, Phenolic foam board insulation in China. After more than 20 years' development, we totally have 10 producing lines for glass wool insulation,5 producing lines for rock wool insulation and more than 30 producing lines for rubber foam insulation.

We had mad OEM production for WANMAIDE which are popular due to the high quality and competitive price all over the world.

Collection

Collection